| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : HWASHI

Model Number : WL-AMF-160K

Certification : CE/CCC/ISO

Place of Origin : China

MOQ : 1 set

Price : negotiation

Payment Terms : L/C, T/T, MoneyGram

Supply Ability : 50 sets per month

Delivery Time : 7-30 working days after received your payment

Packaging Details : sea worthy wooden package

Product Name : HWASHI IBC Long Tube Automatic Pressing and Forming Machine

Application : IBC Long Tube

Size : according to your products

Condition : New

Warranty : 12months

Certificate : CE/CCC/ISO

Service Life : 8-10 years

HWASHI IBC Long Tube Automatic Pressing and Forming Machine

Description Of The IBC Cage Frame Automatic Production Line

The IBC cage frame automatic production line is mainly used to manufacturing the IBC cage frame. It is composed of cage frame automatic welding machine, mesh unloading mechanical arm, turnover table, automatic frame bending machine, locking machine, hole making and punching machine, automatic production line moving mechanical arm. The complete line requires only 3-4 person. Operator only need to do the material loading to the frame welding machine, and do unloading at the end of the line. Also we can equip the line with automatic base frame welding machine and automatic unloading mechanical arm for the base frame.

Running Process Of The IBC Cage Frame Automatic Production Line :

Frame welding——bending——locking——hole punching——unloading——base frame welding——base frame loading——manual screw for base frame and outer frame

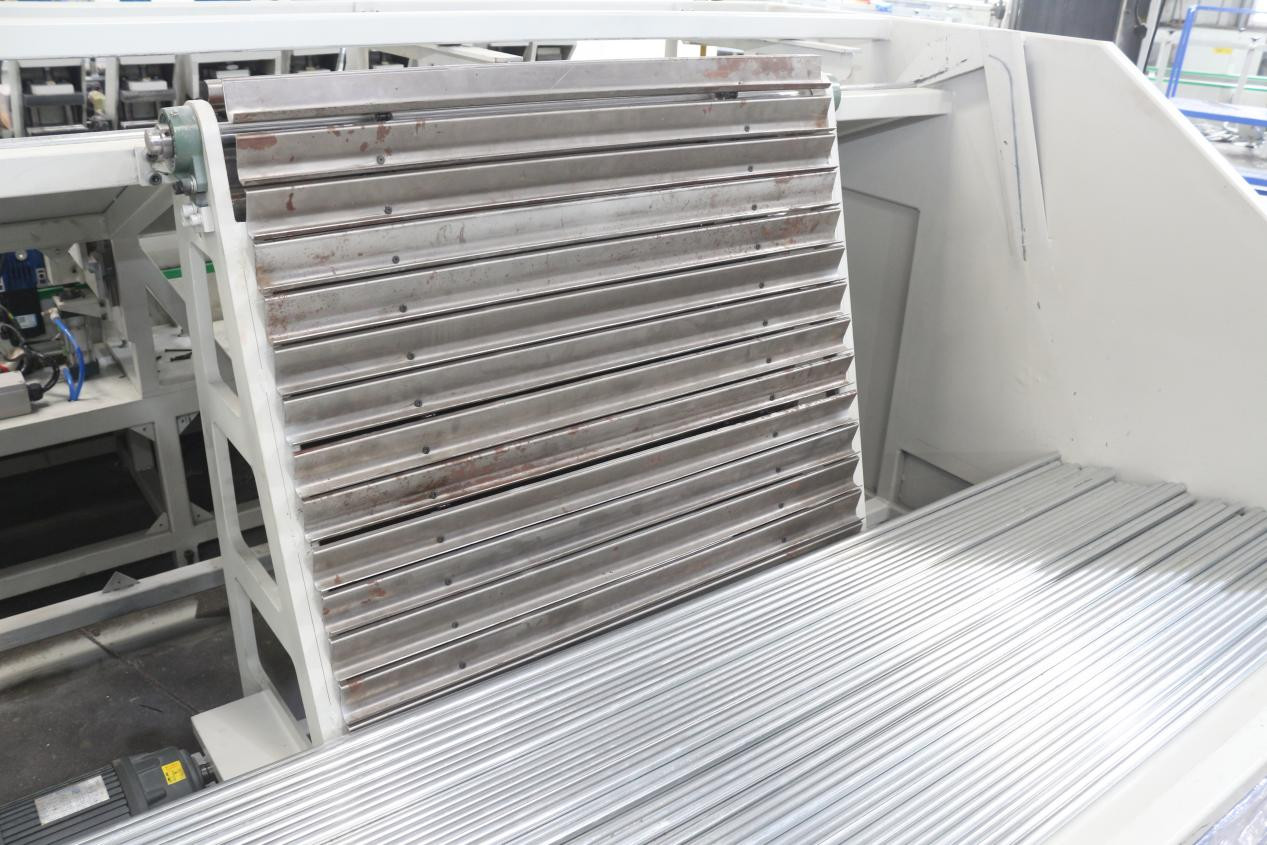

Description Of The Long Tube Pressing and Forming Machine

The long tube pressing and forming machine is a special customized machine for IBC tube processing. It can achieve full automatic pipe feeding, pipe end shrinking, pipe hydraulic pressing, and automatic unloading process. No operator needed. It helps to greatly increase the production rate, and save manpower.

Manually load the round tubes before processing into the hopper.

The feeder will load the pipe to the hydraulic pressing station automatically.

The mechanical arm will pick up two pipes and load them to the hydraulic pressing station to do the pressing and tube end shrinking.

After pressing, the tube will be unloaded to the holding tray, then operator can move the final material to other places.

Technical Data Of The Long Tube Pressing and Forming Machine

| Items | Data |

| Pipe Diameter | Round pipe 18mm (customized) |

| Pressing Source | Hydraulic |

| Pressing Mark Number | 20 |

| Shrinking Function | Yes |

| Each Time Processing Number | 2 pcs |

| Efficiency | 12-15sec/2pcs |

Application Of The Long Tube Pressing and Forming Machine

To do the pressing and tube end shrinking.

Samples Of Long Tube Pressing and Forming Machine

Our Company

|

|

IBC Long Tube Automatic Pressing And Forming Machine Images |